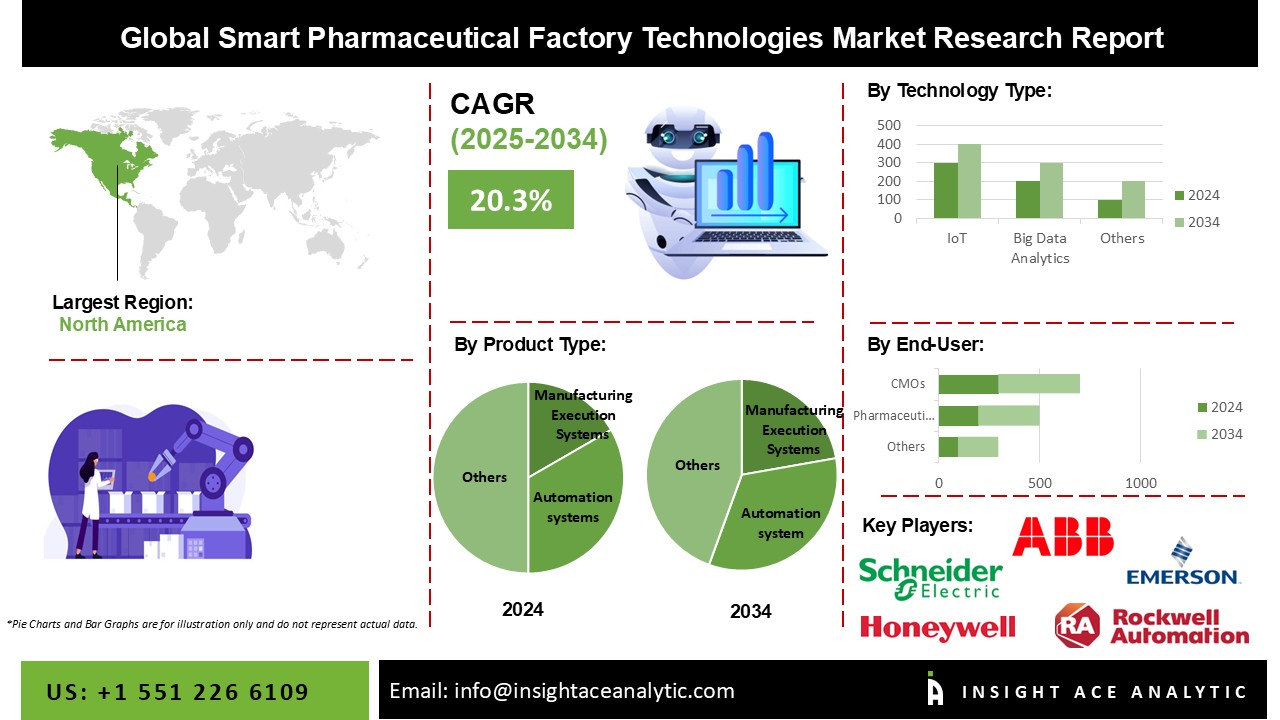

Smart Pharmaceutical Factory Technologies Market Size is predicted to witness at a 20.3% CAGR during the forecast period for 2025-2034.

Pharmaceutical production processes are being revolutionized by a variety of cutting-edge systems and solutions known as smart pharmaceutical factory technologies. Adopting smart pharmaceutical factory technology can increase productivity, improve quality control, increase safety, lower costs, and shorten the time it takes to commercialize pharmaceutical products.

The market for smart pharmaceutical manufacturing technologies is impacted by a number of characteristics that mold its expansion and development. Pharmaceutical companies are under pressure to streamline their processes, cut expenses, and boost production. Automation, robots, and data-driven insights are provided by smart factory technologies, allowing for more streamlined and effective production processes that save money and produce superior operational results.

However, the implementation of remote and virtual operations in pharmaceutical production was required by travel limitations and lockdowns. Manufacturing companies were able to manage operations remotely thanks to smart factory technology that enabled remote monitoring and control of production processes. Platforms for virtual collaboration enabled remote communication and collaboration between teams, suppliers, and partners, assuring smooth operation continuation.

The Smart Pharmaceutical Factory Technologies Market is segmented on the basis of product type, technology type, application, and end-user. Based on product type, the market is segmented as Manufacturing Execution Systems (MES), automation systems, analytical and monitoring systems, and others. The technology type segment includes IoT, Artificial Intelligence (AI) and Machine Learning (ML), big data analytics, robotics and automation, and others. By application, the market is segmented into drug discovery and development, manufacturing and production, quality control and compliance, and others. The end-user segment includes pharmaceutical and biotech companies, CMOs, research institutes and academia.

The automation systems category is expected to hold a major share of the global Smart Pharmaceutical Factory Technologies Market in 2022. This is primarily due to the rising need for efficiency and cost-cutting in the pharmaceutical production process, the COVID-19 pandemic's effects, the focus on patient safety and medicine quality, and government regulatory activities. In addition, developments in automation technology are fueling the market expansion of automation systems.

Automation systems in healthcare can be developed thanks to AI and machine learning. AI-powered systems' advantages include their capacity to assess a lot of patient data, offer real-time insights, and enhance clinical decision-making, which results in more individualized and efficient therapies.

The drug discovery and development segment is projected to grow at a rapid rate in the global Smart Pharmaceutical Factory Technologies Market. The demand for targeted medication for high-quality treatment, the availability of big data, cost and time efficiency, individualized medicine, and partnerships between pharmaceutical and technology companies are some of the market drivers of smart pharmaceutical factory technologies in drug discovery and development. It facilitates the swift adoption of technologies for pharmaceutical manufacture and alters the pharmaceutical sector for faster medication development and discovery.

The North America Smart Pharmaceutical Factory Technologies Market is expected to register the highest market share in terms of revenue in the near future. This is attributed to the growing demand for advanced and automated manufacturing solutions in the pharmaceutical industry, the growing importance of quality control and regulatory compliance, the increasing investment in smart technologies by the major market players, the requirement for cost reduction and manufacturing efficiency in the pharmaceutical industry, the rising emphasis on individualized medicine, and the growing complexity of drug formulations.

Additionally, during the projection period, the market expansion will be made possible by developments in digitization, networking, and cloud computing. Additionally, Asia Pacific is anticipated to experience rapid expansion during the forecast period. This is due to the rising prevalence of chronic diseases and the growing demand for pharmaceutical products. Governments in the Asia Pacific area are aggressively encouraging the deployment of cutting-edge technologies (including the Internet of Things, robotics, and artificial intelligence) as well as the necessity for smart pharmaceutical systems in the event of a COVID-19 pandemic.

| Report Attribute | Specifications |

| Growth Rate CAGR | CAGR of 20.3% from 2025 to 2034 |

| Quantitative Units | Representation of revenue in US$ Bn and CAGR from 2025 to 2034 |

| Historic Year | 2021 to 2024 |

| Forecast Year | 2025-2034 |

| Report Coverage | The forecast of revenue, the position of the company, the competitive market structure, growth prospects, and trends |

| Segments Covered | Product Type, Technology Type, Application, And End-User |

| Regional Scope | North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

| Country Scope | U.S.; Canada; U.K.; Germany; China; India; Japan; Brazil; Mexico; The UK; France; Italy; Spain; South Korea; Southeast Asia |

| Competitive Landscape | Siemens AG, Schneider Electric SE, Honeywell International Inc., Rockwell Automation, Inc., Emerson Electric Co., ABB Ltd., General Electric Company, Yokogawa Electric Corporation, Werum IT Solutions GmbH (part of Körber AG), and Optel Group. |

| Customization Scope | Free customization report with the procurement of the report, Modifications to the regional and segment scope. Particular Geographic competitive landscape. |

| Pricing and Available Payment Methods | Explore pricing alternatives that are customized to your particular study requirements. |

Smart Pharmaceutical Factory Technologies Market By Product Type

Smart Pharmaceutical Factory Technologies Market By Technology Type-

Smart Pharmaceutical Factory Technologies Market By Application-

Smart Pharmaceutical Factory Technologies Market By End-User-

Smart Pharmaceutical Factory Technologies Market By Region-

North America-

Europe-

Asia-Pacific-

Latin America-

Middle East & Africa-

This study employed a multi-step, mixed-method research approach that integrates:

This approach ensures a balanced and validated understanding of both macro- and micro-level market factors influencing the market.

Secondary research for this study involved the collection, review, and analysis of publicly available and paid data sources to build the initial fact base, understand historical market behaviour, identify data gaps, and refine the hypotheses for primary research.

Secondary data for the market study was gathered from multiple credible sources, including:

These sources were used to compile historical data, market volumes/prices, industry trends, technological developments, and competitive insights.

Primary research was conducted to validate secondary data, understand real-time market dynamics, capture price points and adoption trends, and verify the assumptions used in the market modelling.

Primary interviews for this study involved:

Interviews were conducted via:

Primary insights were incorporated into demand modelling, pricing analysis, technology evaluation, and market share estimation.

All collected data were processed and normalized to ensure consistency and comparability across regions and time frames.

The data validation process included:

This ensured that the dataset used for modelling was clean, robust, and reliable.

The bottom-up approach involved aggregating segment-level data, such as:

This method was primarily used when detailed micro-level market data were available.

The top-down approach used macro-level indicators:

This approach was used for segments where granular data were limited or inconsistent.

To ensure accuracy, a triangulated hybrid model was used. This included:

This multi-angle validation yielded the final market size.

Market forecasts were developed using a combination of time-series modelling, adoption curve analysis, and driver-based forecasting tools.

Given inherent uncertainties, three scenarios were constructed:

Sensitivity testing was conducted on key variables, including pricing, demand elasticity, and regional adoption.