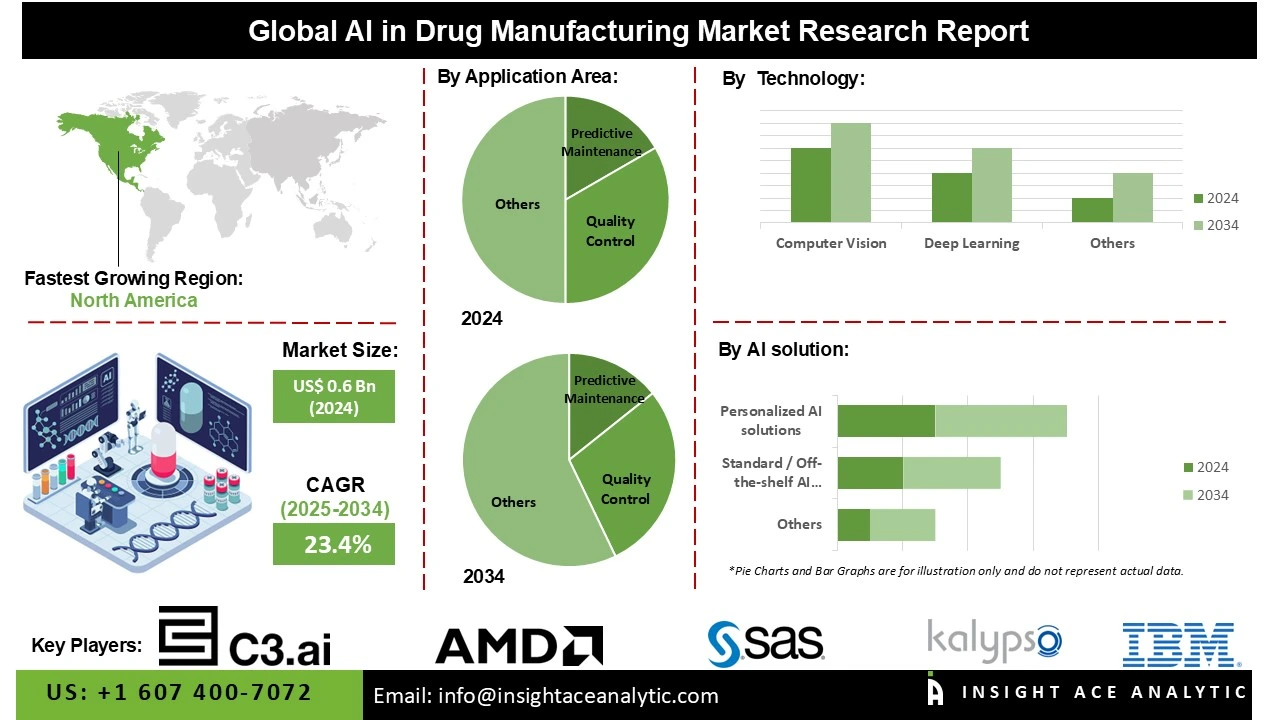

AI in Drug Manufacturing Market Size is valued at US$ 0.6 Bn in 2024 and is predicted to reach US$ 5.0 Bn by the year 2034 at an 23.4% CAGR during the forecast period for 2025-2034.

AI in drug manufacturing refers to the utilisation of artificial intelligence technologies, such as machine learning and predictive analytics, to optimise drug formulation, streamline production processes, enhance quality control, and accelerate pharmaceutical development efficiently. The AI in drug manufacturing market is experiencing rapid expansion as pharmaceutical companies increasingly integrate artificial intelligence to optimize production efficiency and quality control.

AI technologies, including machine learning, predictive analytics, and digital twins, are revolutionising process automation, real-time monitoring, and fault detection. A major driver is the increasing adoption of AI to meet the rising demand for drugs, allowing for faster scale-up, reduced downtime, and enhanced consistency in complex manufacturing environments. Moreover, AI supports predictive maintenance and data-driven decision-making, lowering operational costs while maintaining regulatory compliance. This digital transformation is crucial for meeting the global demands of healthcare and personalised medicine.

The AI in drug manufacturing market is experiencing significant growth as pharmaceutical companies increasingly adopt artificial intelligence to enhance production efficiency, quality control, and predictive maintenance. AI-driven analytics aid in optimising formulation design, real-time monitoring, and minimising human error during complex drug production processes.

The market is further propelled by the presence of advanced pharmaceutical manufacturing infrastructure, which enables seamless integration of AI tools into automated systems. These facilities enable high data availability, robust digital frameworks, and compliance with stringent regulatory standards, thereby accelerating AI adoption and fostering innovation in smart manufacturing and process optimisation across the pharmaceutical industry.

Some of the Key Players in the AI in Drug Manufacturing Market:

· C3.AI

· AMD

· IBM

· Kalypso

· SAS Institute

· Körber Pharma

· SDG Group

· Catalyx

· Elisa Industriq

· Straive

· Axiomtek

· Appinventiv

· Amplelogic

· Precognize

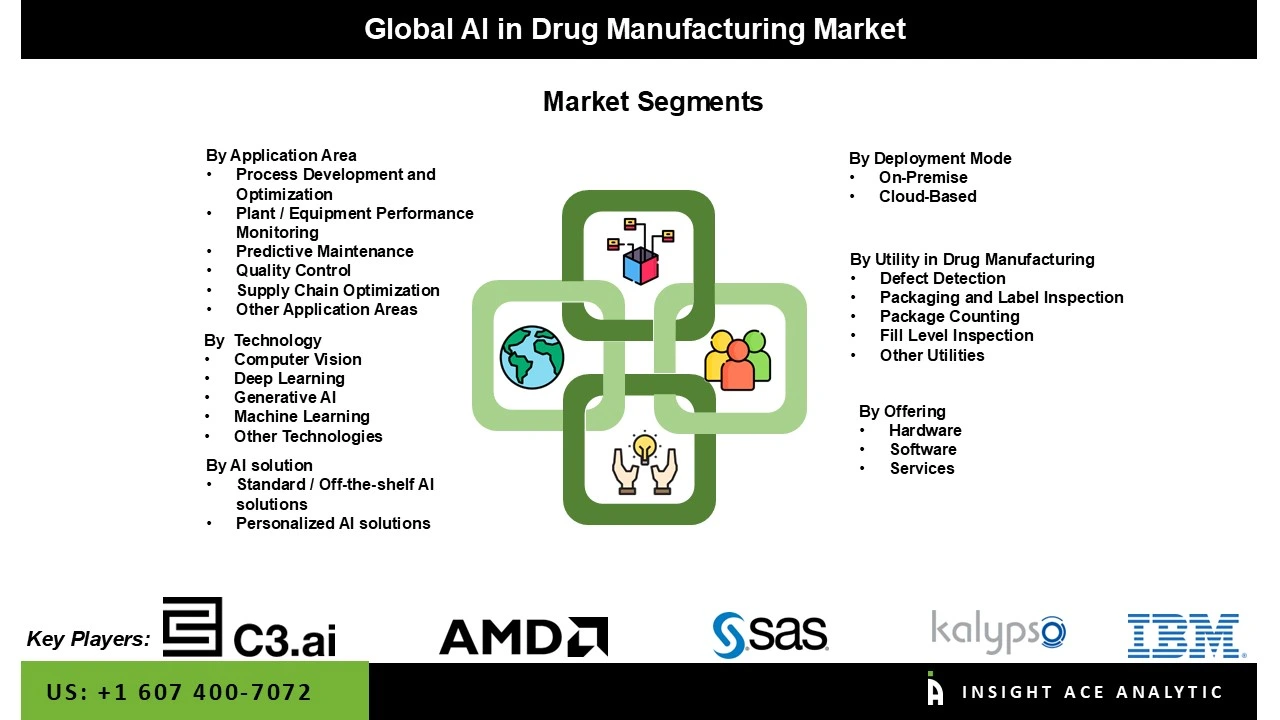

The AI in drug manufacturing market is segmented by type of offering, by mode of deployment, by type of AI solution, by type of technology, by application area, by utility in drug manufacturing and by region. By type of offering, the market is segmented into hardware, software, and services. By mode of deployment, the market is segmented into cloud, and on-premise.

By type of AI solution, the market is segmented into standard/off-the-shelf AI solutions, and personalized AI solutions. By type of technology, the market is segmented into computer vision, deep learning, generative AI, machine learning, and other technologies. By application area, the market is segmented into process development & optimization, plant/equipment performance monitoring, predictive maintenance, quality control, supply chain optimization, and other application areas. By utility in drug manufacturing, the market is segmented into defect detection, packaging & label inspection, package counting, fill level inspection, and other utilities.

In 2024, the software is expected to hold a significant market share as pharmaceutical companies utilise intelligent software to enhance production efficiency, quality, and compliance. AI-powered software offers predictive maintenance, process optimisation, and real-time monitoring, thereby reducing downtime and human error. The primary driver is the growing demand for automation and data-driven decision-making to expedite drug development while supporting regulatory compliance. Furthermore, the incorporation of machine learning algorithms broadens yield forecasting and resource management, changing traditional production into intelligent, adaptable systems.

The AI in drug manufacturing market is dominated by cloud-based solutions, driven by the increasing adoption of cloud-based AI, which enhances operational efficiency and scalability. Cloud platforms enable real-time data sharing, predictive analytics, and process optimisation across multiple manufacturing sites. This facilitates faster decision-making, improved quality control, and decreased production expenses. Moreover, cloud-based AI supports advanced drug formulation, automated quality checks, and continuous monitoring, enabling pharmaceutical firms to accelerate innovation and comply with stringent regulatory standards efficiently.

North America dominates the market for AI in drug manufacturing due to region’s strong pharmaceutical infrastructure and rising adoption of automation to improve production efficiency. AI technologies enable predictive maintenance, process optimisation, and real-time quality inspection, thereby reducing operational costs and errors.

Increasing regulatory support for digitalisation and the presence of leading pharmaceutical and AI companies further stimulate innovation. The increasing demand for customised drugs and the acceleration of drug development timelines also drive market growth in the region.

Moreover, Europe's AI in drug manufacturing market is also fueled due to the region’s strong focus on digital transformation and advanced automation in the pharmaceutical industry. AI enhances productivity by streamlining production processes, improving quality control, and anticipating equipment maintenance requirements. Pharmaceutical firms in Europe are embracing AI for real-time tracking, minimising manufacturing errors, and ensuring regulatory compliance. Also driving the market expansion across the region are increased demand for targeted medicine and government incentives for AI-based innovation.

| Report Attribute | Specifications |

| Market Size Value In 2024 | USD 0.6 Bn |

| Revenue Forecast In 2034 | USD 5.0 Bn |

| Growth Rate CAGR | CAGR of 23.4% from 2025 to 2034 |

| Quantitative Units | Representation of revenue in US$ Bn and CAGR from 2025 to 2034 |

| Historic Year | 2021 to 2024 |

| Forecast Year | 2025-2034 |

| Report Coverage | The forecast of revenue, the position of the company, the competitive market structure, growth prospects, and trends |

| Segments Covered | By Type of Offering, By Mode of Deployment, By Type of AI Solution, By Type of Technology, By Application Area, By Utility in Drug Manufacturing |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

| Country Scope | U.S., Canada, Germany, The UK, France, Italy, Spain, Rest of Europe, China, Japan, India, South Korea, Southeast Asia, Rest of Asia Pacific, Brazil, Argentina, Mexico, Rest of Latin America, GCC Countries, South Africa, Rest of the Middle East and Africa |

| Competitive Landscape | C3.AI, AMD, IBM, Kalypso, SAS Institute, Körber Pharma, SDG Group, Catalyx, Elisa Industriq, Straive, Axiomtek, Appinventiv, Amplelogic and Precognize. |

| Customization Scope | Free customization report with the procurement of the report, Modifications to the regional and segment scope. Geographic competitive landscape. |

| Pricing and Available Payment Methods | Explore pricing alternatives that are customized to your particular study requirements. |

AI in Drug Manufacturing Market by Type of Offering-

· Hardware

· Software

· Services

AI in Drug Manufacturing Market by Mode of Deployment-

· Cloud

· On-premise

AI in Drug Manufacturing Market by Type of AI Solution-

· Standard / Off-the-shelf AI solutions

· Personalized AI solutions

AI in Drug Manufacturing Market by Type of Technology-

· Computer Vision

· Deep Learning

· Generative AI

· Machine Learning

· Other Technologies

AI in Drug Manufacturing Market by Application Area-

· Process Development and Optimization

· Plant / Equipment Performance Monitoring

· Predictive Maintenance

· Quality Control

· Supply Chain Optimization

· Other Application Areas

AI in Drug Manufacturing Market by Utility in Drug Manufacturing-

· Defect Detection

· Packaging and Label Inspection

· Package Counting

· Fill Level Inspection

· Other Utilities

AI in Drug Manufacturing Market by Region-

North America-

· The US

· Canada

Europe-

· Germany

· The UK

· France

· Italy

· Spain

· Rest of Europe

Asia-Pacific-

· China

· Japan

· India

· South Korea

· Southeast Asia

· Rest of Asia Pacific

Latin America-

· Brazil

· Argentina

· Mexico

· Rest of Latin America

Middle East & Africa-

· GCC Countries

· South Africa

· Rest of the Middle East and Africa

This study employed a multi-step, mixed-method research approach that integrates:

This approach ensures a balanced and validated understanding of both macro- and micro-level market factors influencing the market.

Secondary research for this study involved the collection, review, and analysis of publicly available and paid data sources to build the initial fact base, understand historical market behaviour, identify data gaps, and refine the hypotheses for primary research.

Secondary data for the market study was gathered from multiple credible sources, including:

These sources were used to compile historical data, market volumes/prices, industry trends, technological developments, and competitive insights.

Primary research was conducted to validate secondary data, understand real-time market dynamics, capture price points and adoption trends, and verify the assumptions used in the market modelling.

Primary interviews for this study involved:

Interviews were conducted via:

Primary insights were incorporated into demand modelling, pricing analysis, technology evaluation, and market share estimation.

All collected data were processed and normalized to ensure consistency and comparability across regions and time frames.

The data validation process included:

This ensured that the dataset used for modelling was clean, robust, and reliable.

The bottom-up approach involved aggregating segment-level data, such as:

This method was primarily used when detailed micro-level market data were available.

The top-down approach used macro-level indicators:

This approach was used for segments where granular data were limited or inconsistent.

To ensure accuracy, a triangulated hybrid model was used. This included:

This multi-angle validation yielded the final market size.

Market forecasts were developed using a combination of time-series modelling, adoption curve analysis, and driver-based forecasting tools.

Given inherent uncertainties, three scenarios were constructed:

Sensitivity testing was conducted on key variables, including pricing, demand elasticity, and regional adoption.