Biopolymer Packaging Market Size is valued at USD 23.8 Mn in 2024 and is predicted to reach USD 72.0 Mn by the year 2034 at a 11.9% CAGR during the forecast period for 2025-2034.

Biopolymer packaging uses polymers derived from renewable biological sources such as plants, animals, and microorganisms as sustainable alternatives to conventional petroleum-based plastics. These materials address increasing concerns about plastic waste and environmental degradation. Commonly derived from sources like corn, potatoes, and other plants, starch is a cost-effective and biodegradable biopolymer, though it typically exhibits poor moisture barrier properties and limited mechanical strength, which can be enhanced through polymer blending or the addition of reinforcing fillers.

Chitosan, obtained from the shells of crustaceans, offers natural antimicrobial properties, making it particularly useful for active food packaging applications. Effective food packaging must prevent the transmission of gases (such as oxygen and carbon dioxide), moisture, and aromas to preserve freshness and extend shelf life. Additionally, packaging materials must possess adequate tensile strength, tear resistance, and puncture resistance to ensure product protection throughout handling and transportation.

In April 2024, BASF expanded its product portfolio to support environmentally friendly food production by introducing black twines made from its certified biodegradable biopolymer, ecovio. Designed for growing annual fruits and vegetables in commercial greenhouses, these twines made with ecovio T 2206 are certified industrially compostable according to EN13432. This means they can be collected with plant waste after harvesting and sent to industrial composting facilities, where they biodegrade, depending on local regulations. This innovation helps reduce persistent microplastics in organic waste and enables more green waste to be transformed into compost.

Meanwhile, ongoing advancements in biopolymer processing, such as PLA modifications, bio-based composites, and enzyme-assisted biodegradability, have enhanced the usability and durability of bioplastics, broadening their industrial applications. Coupled with stringent government regulations aimed at reducing plastic waste and promoting sustainability, the demand for biodegradable and compostable packaging solutions like biopolymers continues to grow. Rising consumer awareness of plastic pollution has also led to a shift in preferences toward products packaged with environmentally friendly materials. Biopolymer packaging meets this demand by offering a sustainable and responsible alternative to conventional plastic packaging.

The biopolymer packaging market is segmented based on material, application. Based on Material, the market is segmented into polylactic acid (PLA), polyhydroxyalkanoates (PHA), starch blends, polybutylene succinate (PBS), and others. Based on the Application, the market is divided into food & beverages, consumer goods, personal care & cosmetics, healthcare, agriculture, others.

Based on material, the market is segmented into polylactic acid (PLA), polyhydroxyalkanoates (PHA), starch blends, polybutylene succinate (PBS), and others. Among these, the polylactic acid (PLA) segment is expected to have the highest growth rate during the forecast period. Polylactic Acid (PLA) is a biopolymer derived from renewable resources such as corn starch and sugarcane, making it an eco-friendly alternative to conventional petroleum-based plastics. It is biodegradable and compostable under industrial conditions, supporting global sustainability goals and environmental regulations. PLA stands out for its favorable mechanical properties, optical clarity, and ease of processing, which make it highly suitable for a wide range of packaging applications. Furthermore, the increasing implementation of government regulations that promote biodegradable materials has significantly accelerated the adoption of PLA in the packaging industry.

Based on the Application, the market is divided into food & beverages, consumer goods, personal care & cosmetics, healthcare, agriculture, and others. Among these, the food & beverages segment dominates the market. Biopolymer materials such as PLA, PHA, and starch-based bioplastics are widely used in food packaging applications, including wraps, containers, pouches, and bottles. These materials offer excellent barrier properties against moisture and oxygen, ensuring food preservation while reducing reliance on petroleum-based plastics. The growing consumer awareness of environmental issues and the push for sustainable packaging have led to increased adoption of biopolymer packaging in the food & beverages sector.

The region's rich agricultural base provides cost-effective raw materials for biopolymer production, such as cassava and sugarcane, enhancing the competitiveness of biopolymer packaging. Countries like China, Japan, India, and South Korea have implemented stringent regulations against single-use plastics, promoting the adoption of sustainable packaging solutions. The government has implemented tough rules that promote the use of sustainable packaging solutions by penalizing manufacturers who continue to use traditional plastic severely and offering significant subsidies to those moving to the production of biopolymers.

|

Report Attribute |

Specifications |

|

Market Size Value In 2024 |

USD 23.8 Bn |

|

Revenue Forecast In 2034 |

USD 72.0 Bn |

|

Growth Rate CAGR |

CAGR of 11.9% from 2025 to 2034 |

|

Quantitative Units |

Representation of revenue in US$ Mn and CAGR from 2025 to 2034 |

|

Historic Year |

2021 to 2024 |

|

Forecast Year |

2025-2034 |

|

Report Coverage |

The forecast of revenue, the position of the company, the competitive market structure, growth prospects, and trends |

|

Segments Covered |

By Material, Application |

|

Regional Scope |

North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

|

Country Scope |

U.S.; Canada; U.K.; Germany; China; India; Japan; Brazil; Mexico; The UK; France; Italy; Spain; China; Japan; India; South Korea; Southeast Asia; South Korea; South East Asia |

|

Competitive Landscape |

Danimer Scientific, Sphere Group, Vegware Global, VICTOR Güthoff & Partner GmbH, NatureWorks, LLC, BioBag International AS, PLAST-UP, Polybags Ltd, Clondalkin Group Holdings B.V.,Genpak, SIMPAC, TERDEX GmbH, Packman Packaging, Greendot Biopak, Accredo Packaging, Novamont S.p.A., Plantic Technologies, Total Corbion PLA, CJ Biomaterials, BASF SE, Amcor plc, Berry Global, Taghleef Industries, Constantia Flexibles, Mitsubishi Chemical, UFP Technologies |

|

Customization Scope |

Free customization report with the procurement of the report and modifications to the regional and segment scope. Particular Geographic competitive landscape. |

|

Pricing and Available Payment Methods |

Explore pricing alternatives that are customized to your particular study requirements. |

Chapter 1. Methodology and Scope

1.1. Research Methodology

1.2. Research Scope & Assumptions

Chapter 2. Executive Summary

Chapter 3. Global Biopolymer Packaging Market Snapshot

Chapter 4. Global Biopolymer Packaging Market Variables, Trends & Scope

4.1. Market Segmentation & Scope

4.2. Drivers

4.3. Challenges

4.4. Trends

4.5. Investment and Funding Analysis

4.6. Porter's Five Forces Analysis

4.7. Incremental Opportunity Analysis (US$ MN), 2024-2034

4.8. Competitive Landscape & Market Share Analysis, By Key Player (2023)

4.9. Use/impact of AI on Biopolymer Packaging Market Industry Trends

4.10. Global Biopolymer Packaging Market Penetration & Growth Prospect Mapping (US$ Mn), 2021-2034

Chapter 5. Biopolymer Packaging Market Segmentation 1: By Material, Estimates & Trend Analysis

5.1. Market Share by Material, 2024 & 2034

5.2. Market Size Revenue (US$ Million) & Forecasts and Trend Analyses, 2021 to 2034 for the following Material:

5.2.1. Polylactic Acid (PLA)

5.2.2. Polyhydroxyalkanoates (PHA)

5.2.3. Starch Blends

5.2.4. Polybutylene Succinate (PBS)

5.2.5. Others

Chapter 6. Biopolymer Packaging Market Segmentation 2: By Application, Estimates & Trend Analysis

6.1. Market Share by Application, 2024 & 2034

6.2. Market Size Revenue (US$ Million) & Forecasts and Trend Analyses, 2021 to 2034 for the following Application:

6.2.1. Food & Beverages

6.2.2. Consumer Goods

6.2.3. Personal Care & Cosmetics

6.2.4. Healthcare

6.2.5. Agriculture

6.2.6. Others

Chapter 7. Biopolymer Packaging Market Segmentation 3: Regional Estimates & Trend Analysis

7.1. Global Biopolymer Packaging Market, Regional Snapshot 2024 & 2034

7.2. North America

7.2.1. North America Biopolymer Packaging Market Revenue (US$ Million) Estimates and Forecasts by Country, 2021-2034

7.2.1.1. US

7.2.1.2. Canada

7.2.2. North America Biopolymer Packaging Market Revenue (US$ Million) Estimates and Forecasts by Material, 2021-2034

7.2.3. North America Biopolymer Packaging Market Revenue (US$ Million) Estimates and Forecasts by Application, 2021-2034

7.3. Europe

7.3.1. Europe Biopolymer Packaging Market Revenue (US$ Million) Estimates and Forecasts by Country, 2021-2034

7.3.1.1. Germany

7.3.1.2. U.K.

7.3.1.3. France

7.3.1.4. Italy

7.3.1.5. Spain

7.3.1.6. Rest of Europe

7.3.2. Europe Biopolymer Packaging Market Revenue (US$ Million) Estimates and Forecasts by Material, 2021-2034

7.3.3. Europe Biopolymer Packaging Market Revenue (US$ Million) Estimates and Forecasts by Application, 2021-2034

7.4. Asia Pacific

7.4.1. Asia Pacific Biopolymer Packaging Market Revenue (US$ Million) Estimates and Forecasts by Country, 2021-2034

7.4.1.1. India

7.4.1.2. China

7.4.1.3. Japan

7.4.1.4. Australia

7.4.1.5. South Korea

7.4.1.6. Hong Kong

7.4.1.7. Southeast Asia

7.4.1.8. Rest of Asia Pacific

7.4.2. Asia Pacific Biopolymer Packaging Market Revenue (US$ Million) Estimates and Forecasts by Material, 2021-2034

7.4.3. Asia Pacific Biopolymer Packaging Market Revenue (US$ Million) Estimates and Forecasts by Application, 2021-2034

7.5. Latin America

7.5.1. Latin America Biopolymer Packaging Market Revenue (US$ Million) Estimates and Forecasts by Country, 2021-2034

7.5.1.1. Brazil

7.5.1.2. Mexico

7.5.1.3. Rest of Latin America

7.5.2. Latin America Biopolymer Packaging Market Revenue (US$ Million) Estimates and Forecasts by Material, 2021-2034

7.5.3. Latin America Biopolymer Packaging Market Revenue (US$ Million) Estimates and Forecasts by Application, 2021-2034

7.6. Middle East & Africa

7.6.1. Middle East & Africa Wind Turbine Rotor Blade Market Revenue (US$ Million) Estimates and Forecasts by country, 2021-2034

7.6.1.1. GCC Countries

7.6.1.2. Israel

7.6.1.3. South Africa

7.6.1.4. Rest of Middle East and Africa

7.6.2. Middle East & Africa Biopolymer Packaging Market Revenue (US$ Million) Estimates and Forecasts by Material, 2021-2034

7.6.3. Middle East & Africa Biopolymer Packaging Market Revenue (US$ Million) Estimates and Forecasts by Application, 2021-2034

Chapter 8. Competitive Landscape

8.1. Major Mergers and Acquisitions/Strategic Alliances

8.2. Company Profiles

8.2.1. Danimer Scientific

8.2.1.1. Business Overview

8.2.1.2. Key Material/Service Overview

8.2.1.3. Financial Performance

8.2.1.4. Geographical Presence

8.2.1.5. Recent Developments with Business Strategy

8.2.2. Sphere Group

8.2.3. Vegware Global

8.2.4. VICTOR Güthoff & Partner GmbH

8.2.5. NatureWorks, LLC

8.2.6. BioBag International AS

8.2.7. PLAST-UP

8.2.8. Polybags Ltd

8.2.9. Clondalkin Group Holdings B.V.

8.2.10. Genpak

8.2.11. SIMPAC

8.2.12. TERDEX GmbH

8.2.13. Packman Packaging

8.2.14. Greendot Biopak

8.2.15. Accredo Packaging

8.2.16. Novamont S.p.A.

8.2.17. Plantic Technologies

8.2.18. Total Corbion PLA

8.2.19. CJ Biomaterials

8.2.20. BASF SE

8.2.21. Amcor plc

8.2.22. Berry Global

8.2.23. Taghleef Industries

8.2.24. Constantia Flexibles

8.2.25. Mitsubishi Chemical

8.2.26. UFP Technologies

8.2.27. Others

Global Biopolymer Packaging Market - By Material

Global Biopolymer Packaging Market – By Application

Global Biopolymer Packaging Market – By Region

North America-

Europe-

Asia-Pacific-

Latin America-

Middle East & Africa-

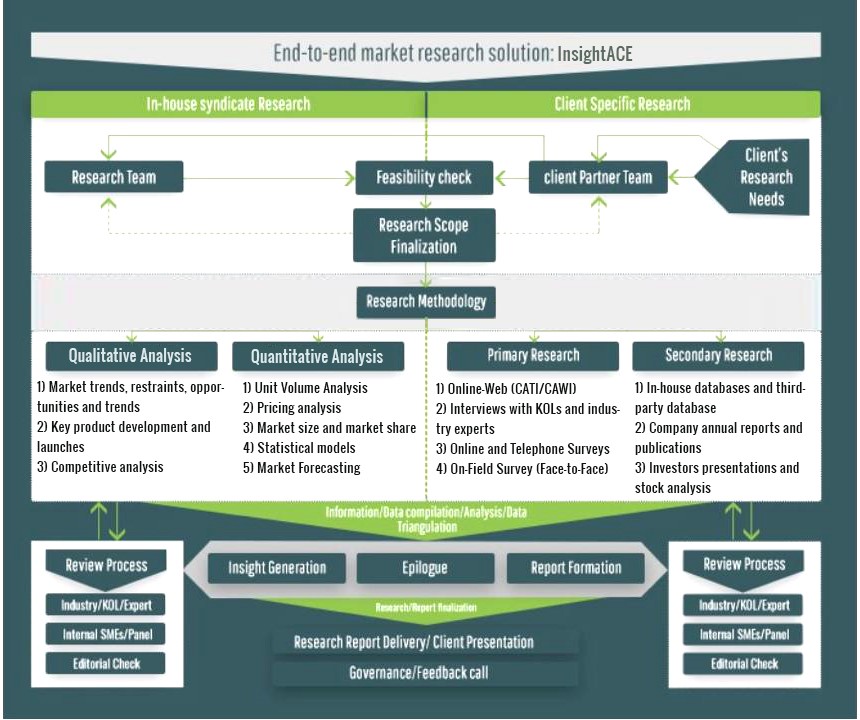

InsightAce Analytic follows a standard and comprehensive market research methodology focused on offering the most accurate and precise market insights. The methods followed for all our market research studies include three significant steps – primary research, secondary research, and data modeling and analysis - to derive the current market size and forecast it over the forecast period. In this study, these three steps were used iteratively to generate valid data points (minimum deviation), which were cross-validated through multiple approaches mentioned below in the data modeling section.

Through secondary research methods, information on the market under study, its peer, and the parent market was collected. This information was then entered into data models. The resulted data points and insights were then validated by primary participants.

Based on additional insights from these primary participants, more directional efforts were put into doing secondary research and optimize data models. This process was repeated till all data models used in the study produced similar results (with minimum deviation). This way, this iterative process was able to generate the most accurate market numbers and qualitative insights.

Secondary research

The secondary research sources that are typically mentioned to include, but are not limited to:

The paid sources for secondary research like Factiva, OneSource, Hoovers, and Statista

Primary Research:

Primary research involves telephonic interviews, e-mail interactions, as well as face-to-face interviews for each market, category, segment, and subsegment across geographies

The contributors who typically take part in such a course include, but are not limited to:

Data Modeling and Analysis:

In the iterative process (mentioned above), data models received inputs from primary as well as secondary sources. But analysts working on these models were the key. They used their extensive knowledge and experience about industry and topic to make changes and fine-tuning these models as per the product/service under study.

The standard data models used while studying this market were the top-down and bottom-up approaches and the company shares analysis model. However, other methods were also used along with these – which were specific to the industry and product/service under study.

To know more about the research methodology used for this study, kindly contact us/click here.